The Clear View of Performance You’ve Been Missing

Scytec DataXchange machine monitoring has unlimited and endlessly configurable manufacturing charts and dashboards that will increase your shop floor performance.

Let us show you what you are missing out on with a personalized demo.

MANUFACTURING DASHBOARDS

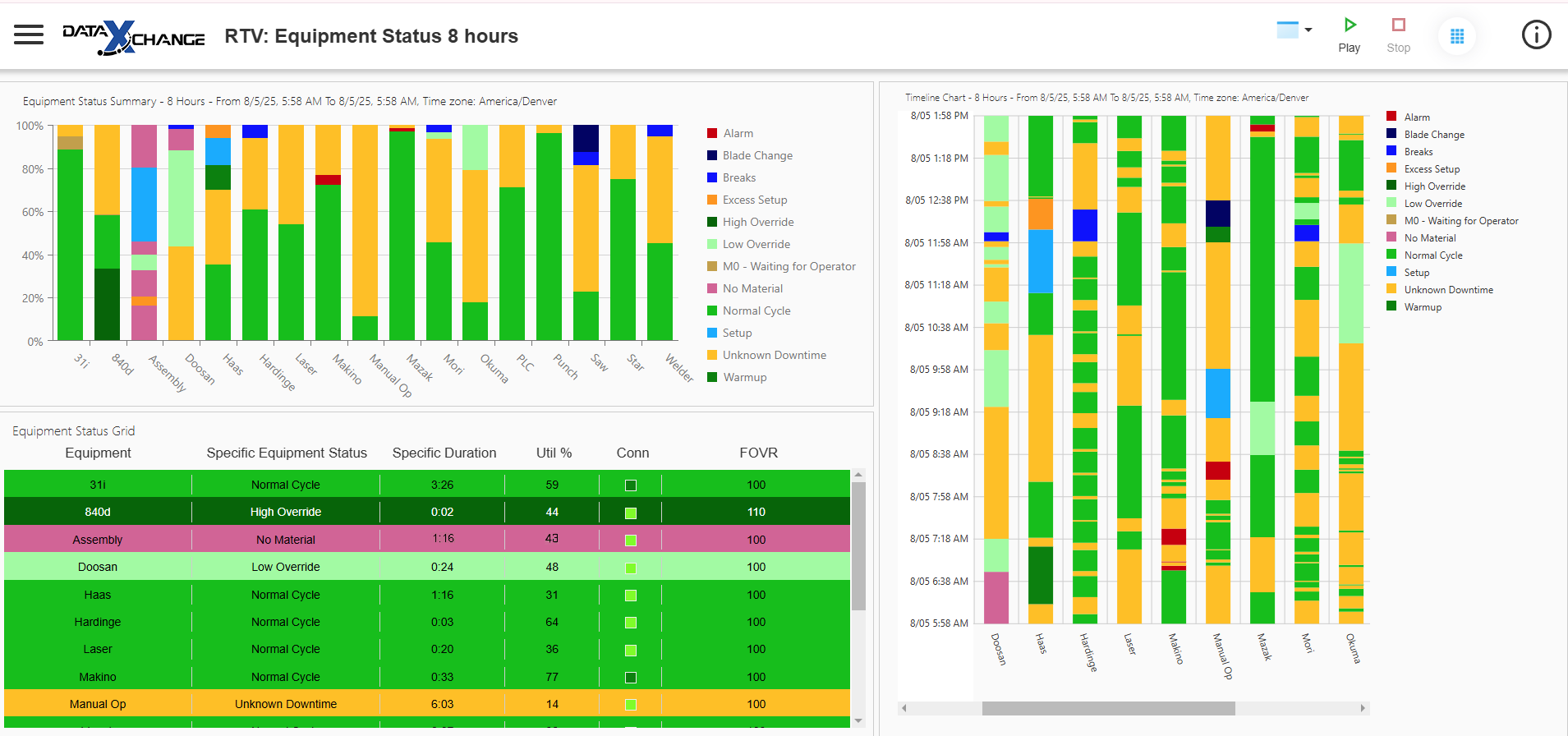

These customizable manufactruing data dashboards help you spot issues faster, make informed decisions, and drive continuous improvement across your shop floor with ease.

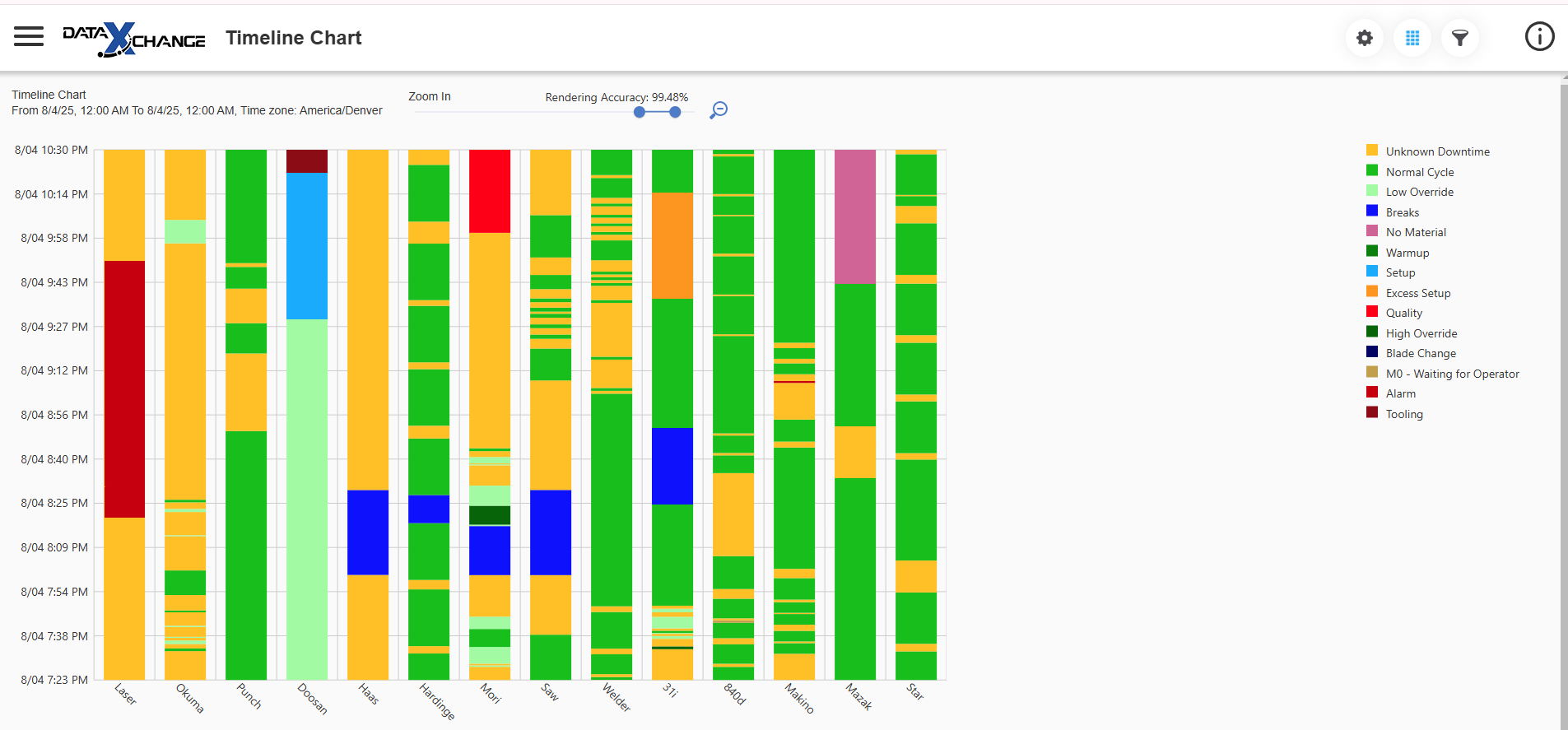

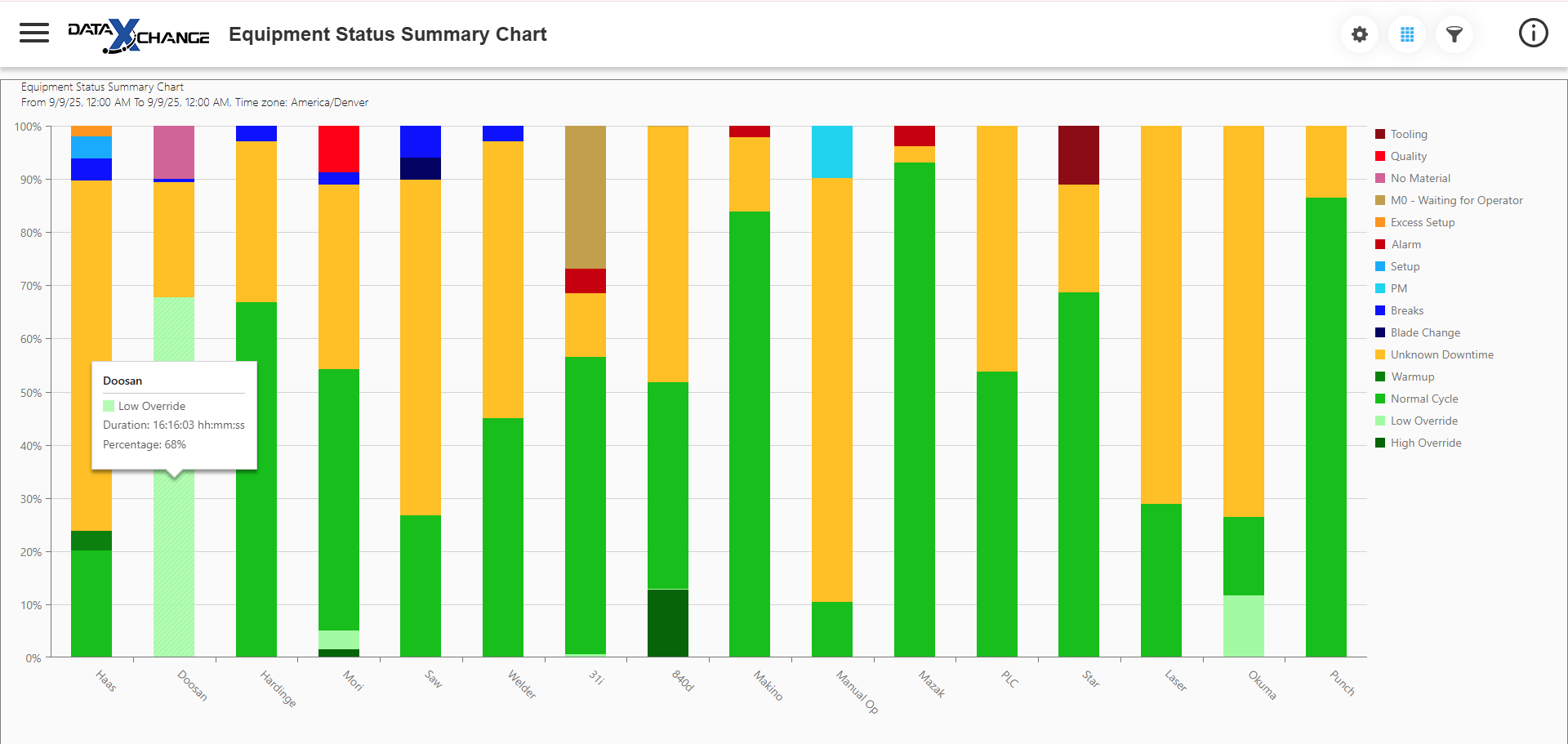

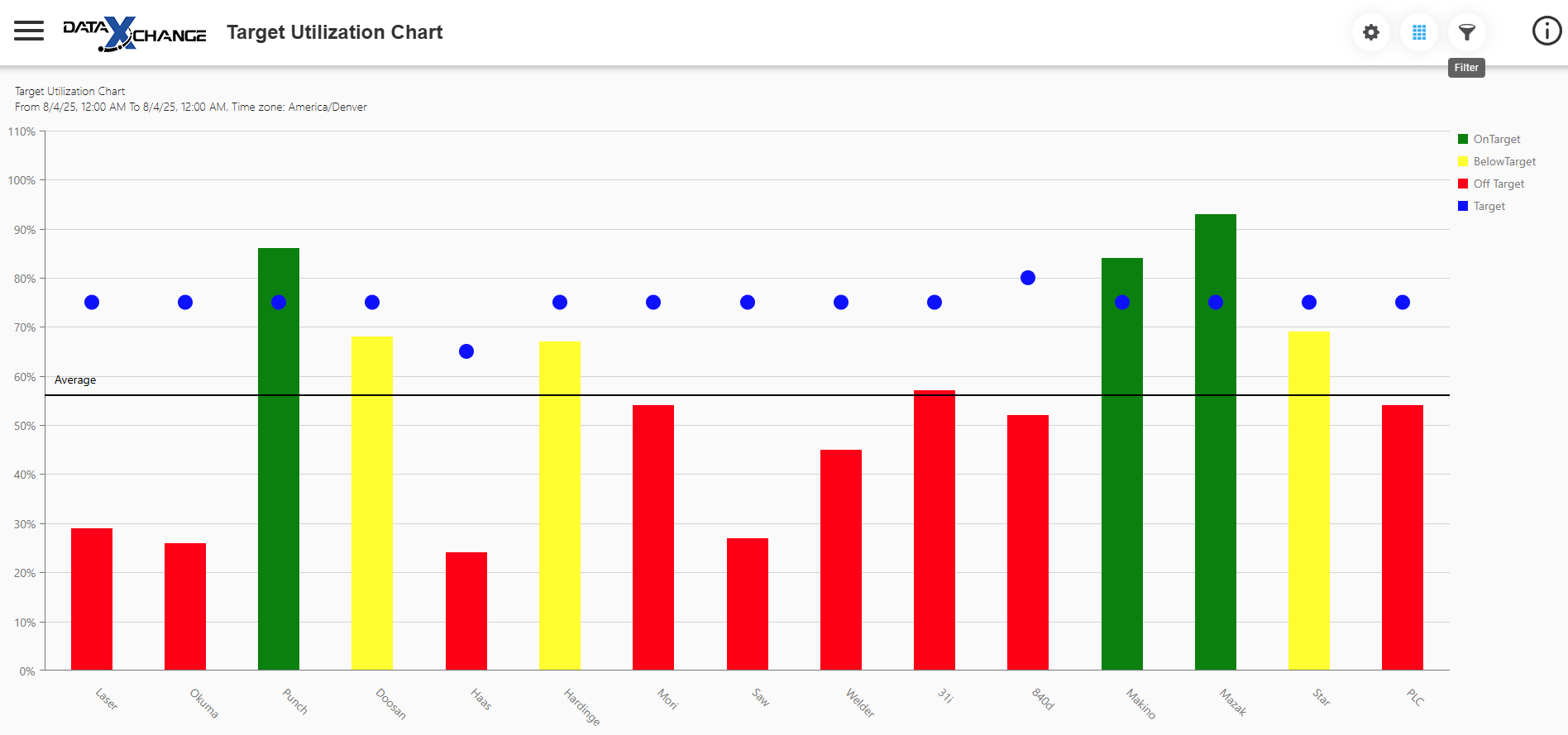

Scytec DataXchange delivers real-time machine monitoring charts and dashboards that transform raw production data into clear, actionable insights. View utilization, downtime, part counts, OEE dashboards, and more in an easy-to-read visual format accessible from any device.

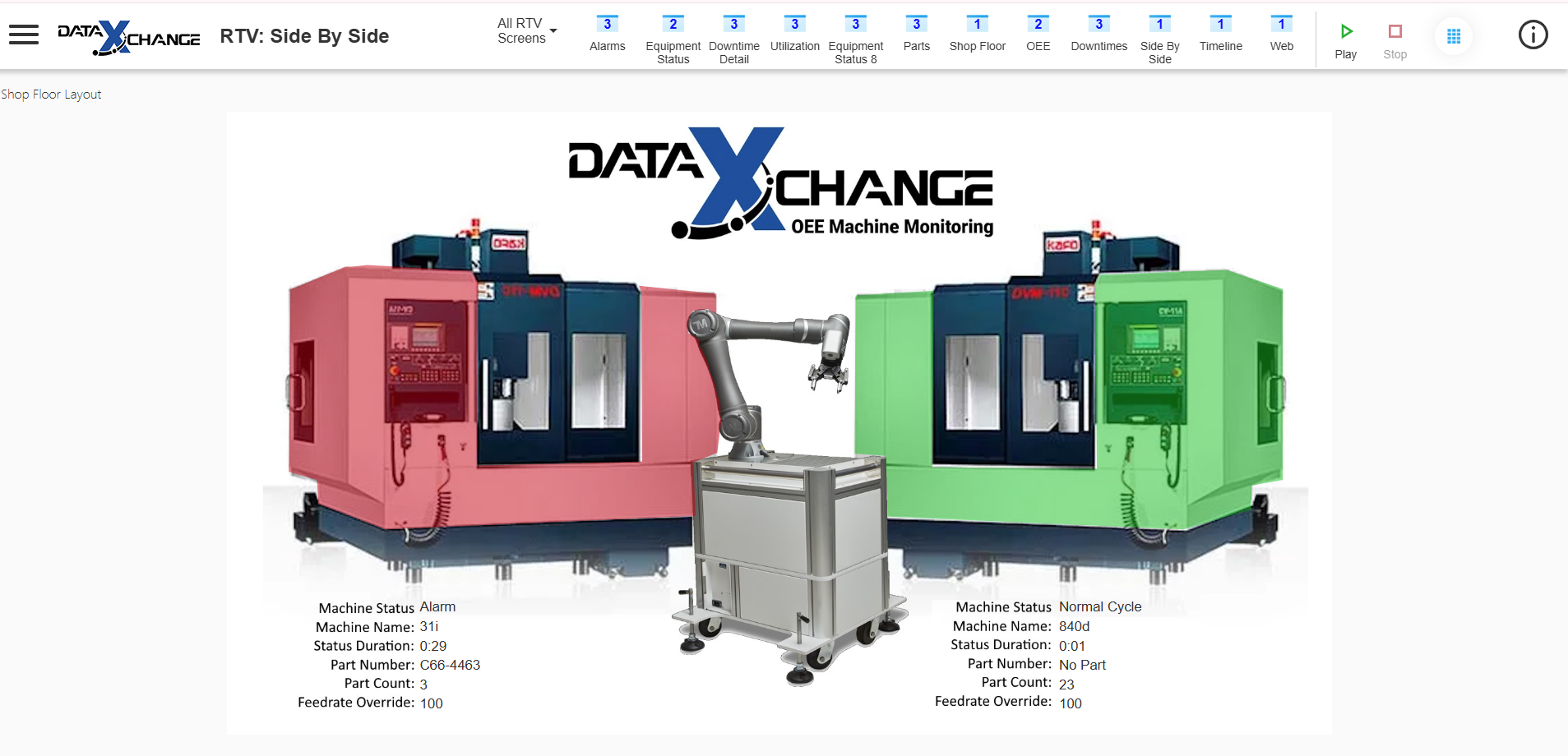

DataXchange Manufacturing Dashboards including Shop Floor Layouts, Alarms, Equipment Status Summaries and more

Why DataXchange Dashboards and Charts?

The manufacturing charts and dashboards in Scytec DataXchange give manufacturers real-time, visual insight into their overall effective efficiency and what’s happening on the shop floor, allowing them to quickly spot issues like machine downtime, bottlenecks, and underperforming machines.

By consolidating production data into easy-to-read, customizable views, these dashboards empower teams to make informed, data-driven decisions on the spot, reducing delays, improving throughput, and targeting the root causes of problems. With clear visibility across all equipment and shifts, manufacturers can transition from reacting to issues after the fact to proactively preventing them, ultimately driving higher efficiency and profitability in your shop floor.

Let Scytec show you how visual smart factory technology can improve your shop floor processes and schedule a demo to see Scytec DataXchange in action below.

MANUFACTURING CHARTS

Visual information helps articulate potential issues more clearly, and the Scytec DataXchange RTV (Real-Time Viewer) delivers visual data to stakeholders throughout the organization through user interfaces uniquely configured to suit the needs of specific users or function areas. Visually, manufacturing data becomes accessible to more people, enabling faster decisions along with the ability to accelerate their respective workflows, leading to faster and better communication of information.

REAL-TIME EQUIPMENT MONITORING

The real-time dashboards in Scytec DataXchange for CNC machines give manufacturers instant visibility into machine status, making it easy to see at a glance whether equipment is running, idle, or experiencing downtime.

By detecting issues the moment they occur, teams can respond faster, reducing unplanned downtime and keeping production on track. Live data enables better decision-making, allowing adjustments to schedules, staffing, or resources on the fly. This leads to higher productivity, improved OEE tracking, and reduced waste by catching events early. DataXchange’s real-time dashboards also promote operator accountability by providing transparent performance metrics across shifts, and with access from desktops, tablets, or mobile devices, managers can monitor operations from anywhere, ensuring the shop floor is always running at peak efficiency.

CNC Machine Monitoring vs. Production Machine Monitoring: Key Differences and Benefits

Learn the key differences between CNC machine monitoring and production machine monitoring, and discover how Scytec DataXchange helps manufacturers maximize efficiency, reduce downtime, and gain real-time shop floor insight.

Understanding Machine Monitoring in the Smart Factory Era

In today’s data-driven manufacturing environment, maximizing equipment efficiency and minimizing downtime are top priorities. Yet achieving these goals is becoming more challenging due to supply chain disruptions, rising material costs, and the shortage of skilled labor. To stay competitive, manufacturers are embracing smart factory machine monitoring systems, tools that deliver real-time insights from shop floor equipment. However, with so many systems on the market, it can be difficult to identify the best fit for your needs. Two of the most common options are CNC machine monitoring and production machine monitoring. While the terms are often used interchangeably, they serve different purposes and deliver distinct types of data.

In this guide from Scytec, we’ll explain the differences between these two platforms and help you determine which is best suited for your manufacturing environment.

What Is CNC Machine Monitoring?

CNC (Computer Numerical Control) machine monitoring focuses on collecting and analyzing data directly from CNC equipment such as mills, lathes, and routers.

This type of monitoring delivers granular, machine-level visibility, tracking parameters like:

- Machine status and OEE (Overall Equipment Effectiveness)

- Spindle speed and load

- Feed rates and axis movements

- Part counts and cycle times

- Alarm codes and downtime reasons

- Overrides (high and low feed or spindle rate)

Advanced platforms like Scytec DataXchange go beyond CNC data collection by also connecting to non-CNC equipment, such as fabrication presses, brakes, and custom assembly lines, through sensors (proximity, fill level, temperature, humidity, etc.). This allows manufacturers to collect real-time data across all machines, regardless of age or brand, providing a unified view of production performance. CNC monitoring is most valuable in precision-driven industries like aerospace, automotive, and medical manufacturing, where process stability, accuracy, and machine health directly affect product quality.

What Is Production Machine Monitoring?

Production machine monitoring, by contrast, takes a broader view of manufacturing performance. It tracks data across the entire production process, not just individual CNC assets.

Rather than focusing on granular machine behavior, production monitoring measures overall plant performance using metrics such as:

- Throughput

- Workflow and process efficiency

- Energy consumption

- Preventive maintenance schedules

Production monitoring platforms often use data listeners or barcode scanners to capture product counts and process flow, making them ideal for high-volume or assembly-line environments. While production machine monitoring provides big-picture operational insight, it typically lacks the machine-level detail that CNC monitoring offers, such as axis data or spindle diagnostics.

Do CNC and Production Monitoring Overlap?

Yes, there’s often overlap between CNC machine monitoring and production machine monitoring. Both systems can track essential KPIs like OEE, downtime, and cycle time. Some production monitoring systems include limited CNC connectivity, while certain CNC platforms can capture plant-wide data when configured correctly.

Ultimately, your choice depends on your operational goals:

- CNC monitoring → ideal for bottleneck identification, precision machining, process optimization, and maintenance insight.

- Production monitoring → best for production throughput.

A versatile platform like Scytec DataXchange bridges both worlds, offering flexible connection methods to capture detailed CNC metrics and broad production insights across the entire facility.

Choosing the Right Machine Monitoring System

When deciding between CNC and production monitoring, consider factors like:

- Scope and purpose – Do you need detailed CNC data or full production visibility?

- Integration needs – Does the platform connect to your ERP, MES, or digital twin software?

- Budget and scalability – Are you looking for flexible pricing without long-term contracts?

- Industry requirements – Are you in a precision environment (CNC-heavy) or a high-volume production line?

Scytec DataXchange was designed to meet all of these needs. The platform offers:

- Flexible month-to-month pricing (no machine minimums)

- Integration with ERP systems like JobBOSS and digital twin software like Vericut

- Support for both high-mix/low-volume and low-mix/high-volume operations

- Multiple connection options for CNCs, sensors, and PLCs

- Cloud and on-premise deployments for maximum control

By consolidating both CNC and production monitoring capabilities, Scytec DataXchange provides a comprehensive smart factory solution for manufacturers of any size.

Why Scytec DataXchange Is the Smart Choice

Whether your focus is on CNC precision or full-plant production visibility, Scytec DataXchange delivers the data insights manufacturers need to stay competitive in the Industry 4.0 era.

With real-time dashboards, historical analytics, and integration flexibility, DataXchange helps you:

- Reduce downtime and improve OEE

- Enhance machine utilization and scheduling

- Gain actionable insight into every stage of production

- Make faster, data-driven decisions

To see how Scytec DataXchange can help modernize your shop floor, schedule a personalized demo today and experience the next generation of smart manufacturing machine monitoring.